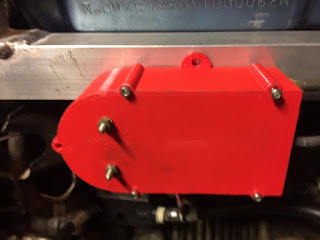

A pre-charge circuit was needed before the controller could safely be connected to the high voltage battery, so I followed the recommended circuit to make up the box below.

Making the final connections on a 320V battery is always a bit nerve-wracking but nothing bad happened. A final check of the control signals using the laptop, and it was time to go for the traditional first very careful trundle around the yard.

It works! Not exactly silent due to the drum brakes being full of rust (and possibly crunched up bits of brake) but that's a minor detail.

Other minor details needed before I can drive it on the road would be:

- Trick the power steering and ABS into thinking the petrol engine is still there, so that they actually work.

- Fit a DC-DC converter to make 12V, instead of relying on a battery temporarily thrown in the boot.

- Fit the main battery charger. I have on the shelf a Manzanita Micros PFC-20B. This is a light weight, air cooled green box that makes nearly 5kW. I have a very early model and it hasn't been the most reliable charger ever, but at least I have been able to repair it myself on the few occasions it's needed it (Rich is generous with the tech support).